Contract development and manufacturing

We Meet Customer Needs With a Fully Integrated Manufacturing Process.

Characteristics of Our Contract Manufacturing and Contract Development

- Designed for specific requirements, contributing to overall system reliability

- Flexible customization in response to customer requests and market changes

- Customization can be made to achieve longer product life

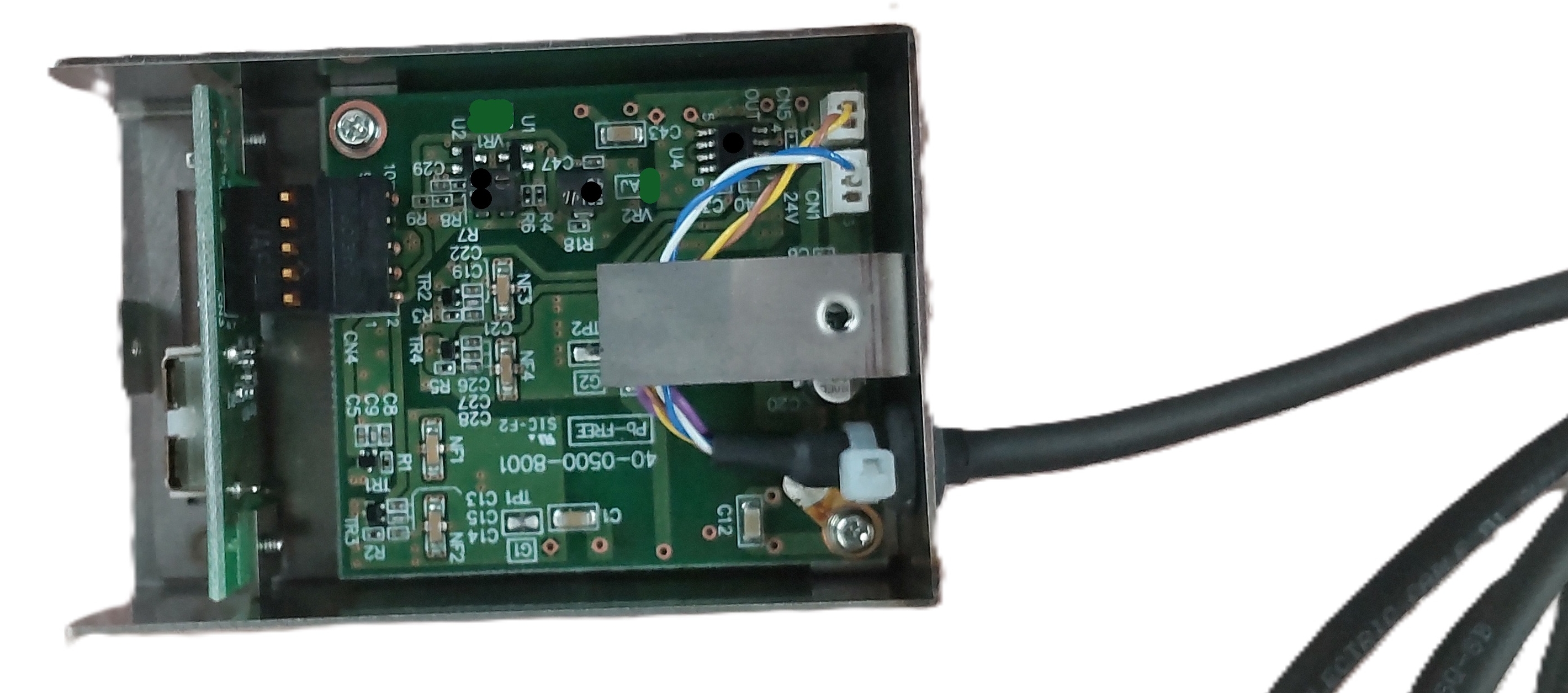

Embedded Device Development

We develop products that match customer requirements, with a focus on controllers for semiconductor manufacturing equipment.

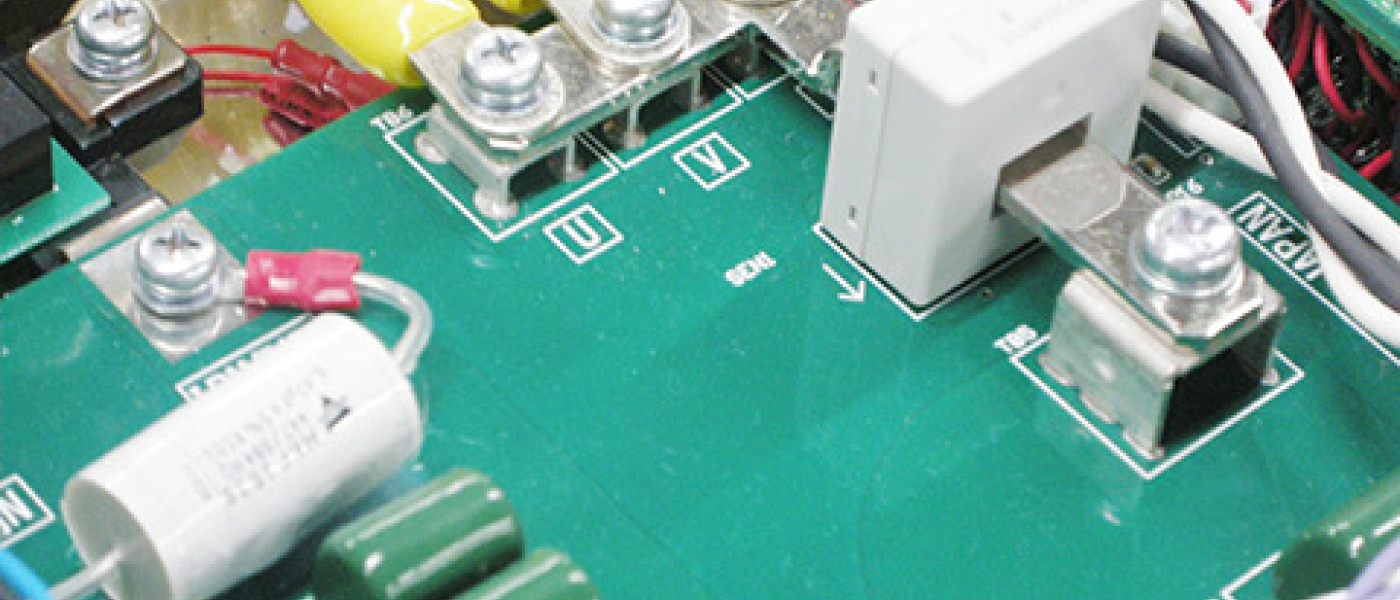

Power Electronics Equipment Development

Custom Module Development

Service Flow

01

Specification Meeting

After receiving your inquiry, we will develop an idea and propose the best solution to meet your needs.

02

Finalized Specifications

Based on the proposal, we will finalize product specifications based on the customer's detailed requirements.

03

Product Design

Based on the finalized specifications, circuit design, board design, housing design, and software design are performed.

04

Prototype Manufacturing

Based on the design, we manufacture several prototypes for customers to evaluate and confirm the actual product shape and function.

05

Design Verification

Design verification is performed on prototypes using measurement instruments such as oscilloscopes and logic analyzers. We also create an environment that is similar to the customer's environment and conduct in-house evaluations. After this, we deliver the prototype to the customer.

06

Customer Evaluation

The customer evaluates the delivered prototype.

07

Mass Production Prototyping/Mass Production Manufacturing

Depending on the customer's requirements, we will conduct mass production prototyping with dozens of units to brush up the mass production quality before starting mass production.

After that, we manufacture products from one unit to several thousand units, depending on the customer's requirements. In manufacturing, we strive to ensure quality not only by procuring parts but also by inspecting all shipments.

Examples of Development Achievements

Electronics & Production Equipment Manufacturers

F社

Measuring amplifiers

EMS (contract manufacturing)

Service Flow

01

Parts Procurement

We obtain parts from each manufacturer through routes that ensure quality. If necessary, we also purchase directly from overseas.

02

Board Mounting

For surface mounting only, we can handle board sizes from 50x100mm to 500mm to 400mm. The smallest mounted components can be up to 0402. We can handle a wide range of production quantities, from a few lots to several thousand pieces. For DIP mounting, machine mounting is available for board sizes up to 300x500mm. For other sizes, we use hand soldering.

03

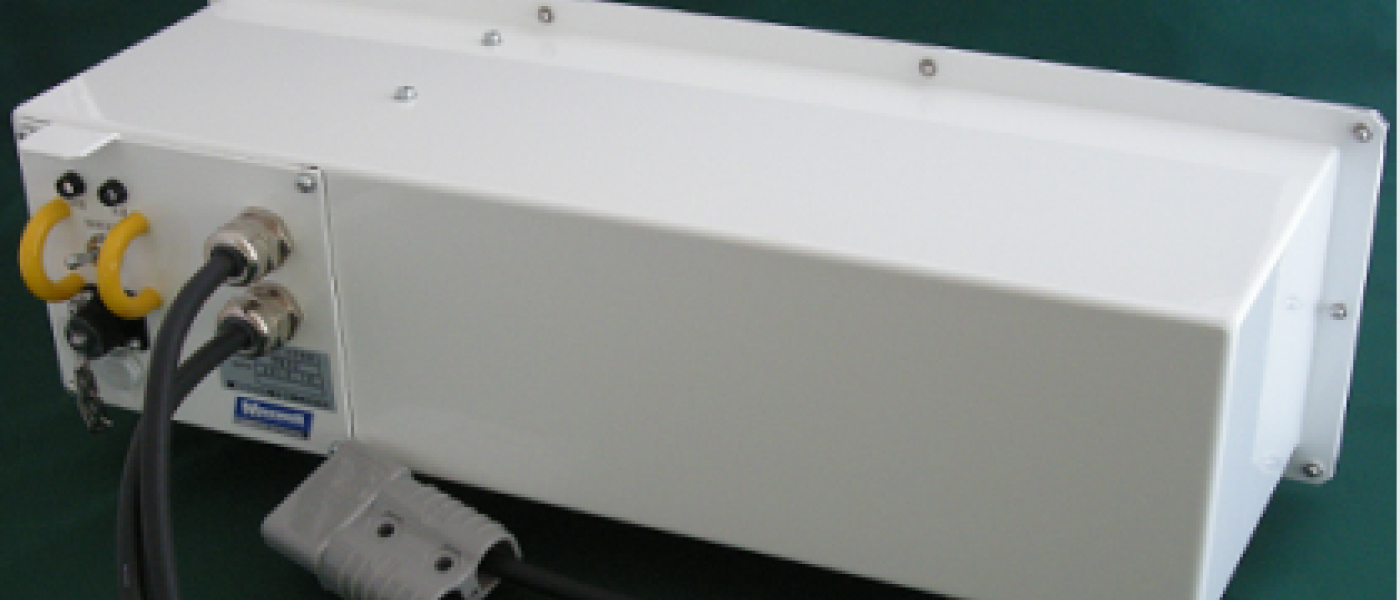

Assembly and Wiring

We can meet a variety of needs, from a single cable to wiring inside a large enclosure, and mixed wiring of power lines and signal lines.

04

Functionality testing

We establish inspection jigs and procedures for each individual product and conduct 100% functional inspections.

05

Packing and shipping

We will ship according to your packaging specifications.

What quantity can you produce?

We can handle production quantities ranging from a few pieces to several thousand pieces.

Is it possible to handle just the pattern design?

Yes, we can. For details, please contact us through our development and manufacturing inquiries.

Is it possible to provide development only?

We give priority to projects involving prototype manufacturing and mass production of products.