Owned Equipment

With an integrated manufacturing system from design to manufacturing, we respond to customer needs.

Utilizing our extensive manufacturing know-how, we are able to quickly develop and manufacture high-quality products. We can flexibly respond to customization according to the diverse needs of our customers and propose the optimal solution. With our services that combine technical capabilities and experience, we support the entire process from product development to manufacturing.

Main Facilities

Mounter AM100 (Panasonic)

It can handle electronic components at high speed and with high precision, and plays a very important role in the production of large-scale electronic products.

- Substrate size (mm)

- L50×W50~L510×W460

- Corresponding part dimensions

- 0402 Chip~L 120 × W 90 or L 150 × W 25

Reflow SNR-840GT(SMIC)

By heating the printed circuit board and components at a constant temperature, the solder paste melts and connects the components to the board. Temperature control is very important. Depending on the type of solder and the characteristics of the substrate, an optimal temperature profile is required. The reflow furnace precisely controls this.

- Substrate size (mm)

- L100×W50~L500×W400

In-Circuit Tester APT-7400cJ(TAKAYA)

This is a test equipment for inspecting whether components and wiring on a printed circuit board operate correctly. It helps to ensure that each component on the board is connected correctly to ensure quality and reliability.

3D Image Inspection System VT-S730 (Omron)

In manufacturing and quality control processes, it is a device that inspects the three-dimensional shape and appearance of products and parts. The device uses cameras and sensors to capture high-resolution images of the surface of the object and generates a 3D model to detect defects and dimensional deviations.

- Substrate size (mm)

- L50×W50~L510×W460

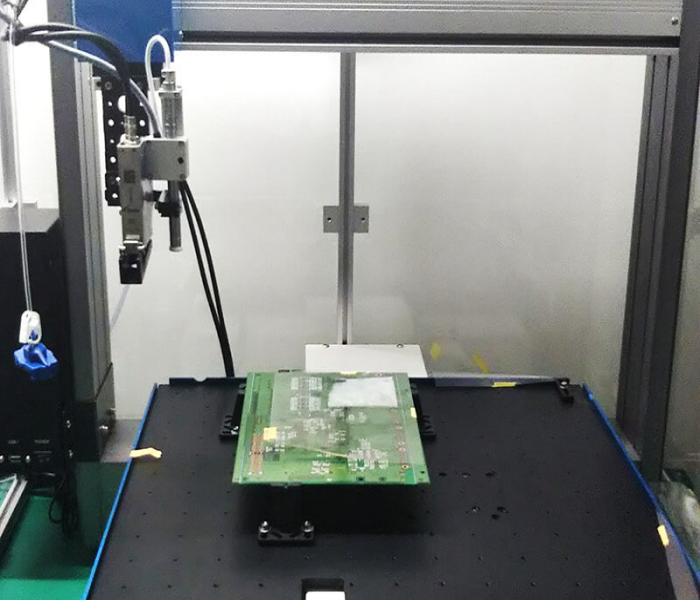

Dispensing System (Coating Machine)

E5V (Nordson)

This is a dispensing system used for the application of coating agents. It provides uniform and high-quality coating application. The automated process improves the efficiency of the coating process and ensures a consistent finish. E5V helps to protect and improve product performance, and helps to improve the quality and productivity of the manufacturing process.

- Maximum working area (mm)

- X450×Y500×Z150

Faber laser welding machine LS-1000(IPG Photonics)

It is a device that uses high-power laser light to precisely weld metal parts, especially for terminal welding of EDLC (electric double layer capacitors). This enables high-speed and high-precision welding, which is widely used in industries such as automotive, aerospace, and medical devices.

- output

- 1kW

Electronic load device NT-AA-KE-L (Measurement & Technology Research Institute) 3 units

This equipment uses high-power laser light to weld metal parts with precision, especially EDLC (electric double layer capacitor) terminals at high speed and high precision. It is widely used in various industrial fields such as automotive, aerospace, and medical devices. (tentative)

- Rated Capacity

- 10kW

- When using 3 units in parallel

- 30kW

Power Factor Variable Load Device 3U-2.10KS (Shoei Electronics Industry)

In the test and simulation of power systems, it is a device that can adjust the power factor of the load (a value determined by the phase difference between voltage and current). This makes it possible to evaluate the performance and operation of power systems and equipment under different load conditions. (tentative)

- Load Capacity

- 10kVA

Temperature Chambers FX224P (Kusumoto Kasei)

It is a device that maintains a constant internal temperature and is used when precise temperature control is required in experiments and manufacturing processes. This eliminates the effects of temperature changes and enables testing and manufacturing in a stable environment. (tentative)

- Room Capacity

- 265L

- Temperature range

- -20℃〜100℃

- Temperature range

- 20%RH~98%RH

Other Facilities and Equipment

| name | Model | maker | Number |

|---|---|---|---|

| printing press | NM-EJP6A | Panasonic | 1 |

| Mounter | KE-2060M | JUKI | 1 |

| Reflow | ARY-540Spw-7Z | YAMATO | 1 |

| flow | ECOPASCAL300 | Senju Metals | 1 |

| Substrate divider | MKC-400 | Technitron Supply | 1 |

| Electrical wire cutting equipment | EC3300 | Schleuniger | 1 |

| Electrical wire stripping machine | US2300 | Schleuniger | 1 |

| BGA Microscope | MS-1000A | Micro Square | 1 |

| Insulation resistance meter | SM-8215 | HIOKI | 1 |

| Dielectric pressure gauge | TOS5050A | KIKUSUI | 1 |

| Noise Simulator | INS-4020 | Noise Research Institute | 1 |

| Electrostatic simulator | KES4021 | KIKUSUI | 1 |

| Power Analyzer | 3390 | HIOKI | 1 |

| Electronic load equipment | FK-3-1000-L | Takasago | 1 |

Contract development and manufacturing

We provide high-quality contract manufacturing and development services by making full use of state-of-the-art equipment. In order to meet the diverse needs of our customers, we can handle a wide range of equipment, from precision equipment to large-scale equipment.